Air Pollution Control Systems

With the intent to effectively prevent the air pollution, we manufacture and supply superior quality air pollution control systems. Precision designed, these systems are used in diverse industries all across the globe. Use of sophisticated technology and engineering expertise enables us to offer them as per the demands of our clients.

Wet Scrubber

We manufacture and supply of wet scrubber system for foundries, boiler fluegas filtration,DG set, metal finshing, powder coating, anodizing and automobile industries. capacity ranges from 2000 cu.m/hr to 4,00,000 cu.m/hr

Other Information

- Pay Mode Terms: L/C (Letter of Credit)

- Production Capacity: as per customer requirement

- Minimum Order Quantity: one Set/Sets

- Delivery Time: one month

- Port of Dispatch: any south indian port

- Packaging Details: wooden packing

Pulse Jet Bag Filter

GTS PROJECTS India P Ltd offers Reverse pulse jat bag filter or it is called as Dust Extraction system. The system consist of the following components:

- Cassettes – polyester Needlefelt

- Spring Clips

- Distant Mats

- Segment Frames

- Bag Support Assembly

- Pyramidal Hopper

- Supporting Structures

- Platform with railing and Ladder

- Double Flap Valve

- Induced Draft Fan Assembly

- U-Tube Manometer

- Junction Box on the filter chamber wired upto solenoid Valve

- Air compresser to suply instrument air

Retrofitted Emission Control System for DG Set

Why GTS PROJECTS’s Retrofitted Emission Control Equipment (Wet Scrubber System for DG Set) Required?

“The Emission including Particulate matters due to operation of Generators set has also been identified as one of the sources of air pollution in Tamilnadu. There is a plan for a national level target of 30% reduction of PM 2.5 and PM10 concentration in the Ambient Air under the National Clear Air Program(NCAP).

To Achieve the same TN Govt have taken an initiative to reduce the emissions of Generator sets used by the people in Tamilnadu. TN Govt have requested all the people who are using generators using 125kVA and above to fix Retrofit Equipment or a device to reduce the emissions from the Diesel Generator sets.

GTS PROJECTS’s Retrofitted Emission Control System for DG Set

GTS PROJECTS’s Retrofitted Emission Control System is the device to remove emissions from the Diesel Generator engine exhaust flue gas. Retrofits can be very effective at reducing emissions, eliminating up to 70% – 90 % of pollutants/constituents/particulate matters present in the flue-gas.

Our Retrofitted System will not only reduce air pollution but also enable our cities to rank higher on the live ability standards.

DG sets generates large amount of pollutants. It is estimated that at the various places like metro stations, Industries, Commercial buildings, IT Parks etc., DG sets are used for even fifteen minutes day can add many tons of particulate matter from all the diesel.

Govt have passed directions to all states and union territories, ensuring a strict enforcement of the National Clean Air Plan to make suitable provisions on control of pollution from diesel generators. in-use and also to include control and mitigation measures related to these generators as per NGT Guidelines, CPCB Norms etc.

Permissible limit

PM – 150 mg/Nm3

SO2 – 100 ppm

NOX – 50 ppm

Dust Collector System

GTS PROJECTS India P Ltd offers Dust collector systems in varies capacities of dust ladden air flow rate, varoius temperature and different concentration of Dust particles.

The bag filter cloths are selcted based on the temperature, type and particle size of dust and SPM particles present in the air stream.

Venturi Scrubber

We offer a comprehensive range of air pollution control systems, which are designed by us using cutting edge technology. Available in standard as well as customized specifications, these systems meet the varied requirements of air handling applications in various industries like: Pharmaceutical Industries, Power Plants, Foundries, Chemical Industries.

Cement Engineering Under this air pollution control system, we offer a wide range of scrubber technologies to rigorously meet clean air norms. These scrubber technologies are enlisted below:

- Jet ejector scrubbers

- Bag filters and Cyclones

- Packed wet scrubbers

- Venturi Scrubbers & Particulate collection systems

- Centrifugal blowers

- Acid Fumes scrubbers & exhaust systems

Induced Draft Fan (I.D FANS)

We have in store for our clients, a technically upgraded assortment of induced draft fans that are superior in performance as well as cost efficient. Offered in numerous specifications to choose from, these induced draft fans can be customized for our clients, at industry leading prices.

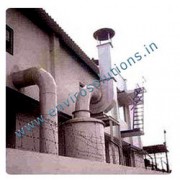

Chimeney / Stack

GTS PROJECTS India P Ltd undertake Fabrication, supply, erection and commissioning of various types and size of Chimney and Stack. We undertake site fabrication, civil works and installation.

Other Information

- Pay Mode Terms: Other

- Production Capacity: any quantity

- Delivery Time: one month

Venturi and Packed Bed Wet Scrubber

We provide quality range of Air Pollution Control Systems, which is also known as scrubbers. Our range uses liquid medium (generally water) to remove particulate and gaseous contaminants from industrial exhaust systems.

Cyclone Separator

GTS PROJECTS INDIA P LTD offers Design, Fabrication/manufacture, supply, Erection, testing and commissioning of Packed bed wet scrubber system. The wet scrubber system consist of the following components including all necessary piping, instruments.

- Wet scrubber chamber or packing tower

- Shells, heads, skirt/leg/lug/saddle supports and anchor chairs.

- Support for internals and other parts

- Induced draft blower with motor, belt, pulley and belt guard

- Vibration isolator

- jackscrews (Optional)

- Painting- anticorrosive

- Manhole/handhole

- Internal distributor/pipe, vortex breaker, baffle plate,

- Water distributor and packing.

- Air flow Capacity control equipment (VFD)

- Water recirculation pump

- Spare parts and Special tools if customer required.

- Noise control Foundation.

Dry scrubber – Odour Removal

GTS PROJECTS India P Ltd are the manufacturer/ fabricator of dry scrubber (high efficiency) which is mainly used for oil removal, odour removal and other adsorption purpose. The system provided with the following components:

- Induced Draft Fan

- Dry Scrubber Chamber

- Packing Material (Adsorption Purpose)

- Ducting Works

- Chimney and Suction Works

PP-FRP Ducting

GTS PROJECTS India P Ltd offers Horizontal spray type scrubbers for process air treatment where temperature at ambient where different gas constituents to be separated or recovered.

The waste gas exhausted at the process system reaches through the crude gas piping into the cyclone separator. Here dust and sand particles are given off at filter traps. The Pre-cleaned exhaust air reaches through the fan into the scrubber.

The exhaust air is brought in by a special distribution system into the washing liquid (Sulphuric acid/phosphoric acid). By the very fine distribution of the gas in the liquid and the turbulences arising at this, an active contact zone is produced.

The fan integrated at the pure gas side of the scrubber blows the cleaned exhaust air about the chimney into the free atmosphere. These type of wet scrubber ideal for removal of Ammonia or amine present in the waste air stream.